Let Geoinvestigate quote for your next coal mining risk assessment (CMRA), coal mining investigation, mining report, mine shaft investigation, desk study, ground investigation, borehole investigation, site investigation, geotechnical, geo-environmental or contaminated land investigation in Stoke on Trent, Macclesfield Stoke, Northwich, Leek, Stafford, Shrewsbury, Telford, Chester or Staffordshire.

With over 18 years in the business, several regional offices offering a nationwide service including an office in Solihull, highly qualified and experienced professional staff, and its own drilling equipment, Geoinvestigate is best placed to give the most competitive and professional coal mining service

If you need assistance with a planning application or a coal mining risk assessment (CMRA), a general site investigation or any of our other services please contact us at our Manchester Office.

Call 01613 272613 or email enquiries @geoinvesigate.co.uk

Or if your enquiry is just about Coal Mining CALL FREE on 0800 1712011

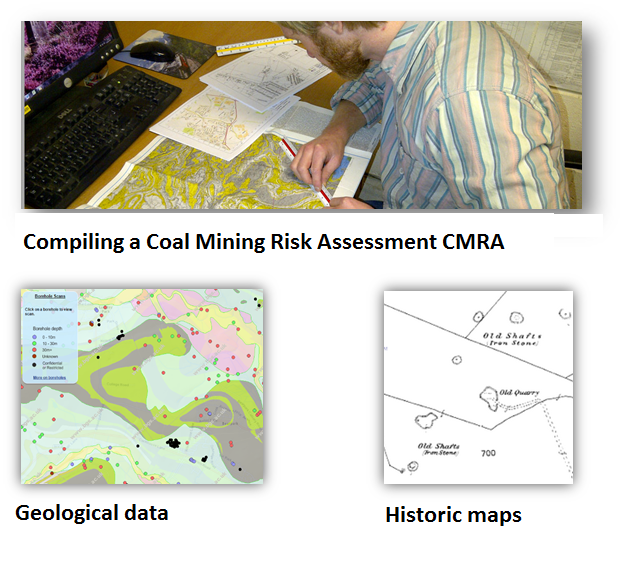

The following article gives a brief background to historic mining activity in the Stoke on Trent and Staffordshire Coalfield and the services Geoinvestigate provide to enable house buyers, home owners, developers, architects and engineers to build safely in respect of the regions coal mining legacy.

Mining and Industrial History of the Staffordshire Coalfield

The North Staffordshire Coalfield is an historic coalfield in the County of Staffordshire, England. The Coalfield covering an area of almost 100 square miles (260 km2) and that area is virtually wholly contained within the limits of the city of Stoke on Trent and the borough of Newcastle under Lyme. There are three other smaller coalfields which are associated with the North Staffs field these being the much smaller Shaffalong and Goldsitch Moss Coalfields near to Leek and the Cheadle Coalfield.

There is a record of ancient coal mining in North Staffordshire as early as the 13th century by the monks at Hulton Abbey but the industry grew during the Industrial Revolution when coal mined in North Staffordshire was used in the regions famous Pottery industry of the Potteries, and also the local Iron industry as ironstone deposits were also found with the coal in certain areas.

The pinnacle of the industry in this area was in the period before the First World War when over 20,000 men worked in the Staffordshire coal mining industry and over 50 collieries and coal pits were in operation. Post nationalisation in 1947 the North Staffs coal industry was gradually scaled down in size as the smaller pits were closed or merged with the larger, more modern mines. The industry began its final decline after the (UK miners’ strike (1984–85) more commonly known as the 1984-85 Miners’ Strike and the last deep coal mine in the coalfield, Silverdale, was closed on Christmas Eve 1998.

Geology

The superficial geology in this area predominantly consists of Devensian Glacial Tills, which overlie the Middle and Upper Pennine Coal Measures; the same sequences of sandstones, mudstones and coal seams as forms the impressive coalfields of Lancashire. The North Staffordshire Coalfield is a compact and heavily faulted coalfield, which is triangular and troughed like a saucer in its shape. However for its relatively small size it has a tremendous number and variety of workable seams.

Seams within the Middle Coal Measures (MCM) include the Winghay, Rowhurst, Burnwood, Moss, Five Feet, Yard, Ragman, Hams, Bellringer, Ten Feet, Bowling Alley, Holly Lane, Hard Mine.

Seams within the Lower Coal Measures (LCM) include Banbury, Cockshead, Bullhurst, Winpenny, Diamond, Brights, King, Crabtree, Two Feet.

Borehole Investigation of Shallow Coal Mining

Over the past 5 months Geoinvestigate’s new compact microdrill system has proven its worth and that it’s just the answer for investigating The Black Countrys coal mining legacy. Microdrill offers restricted access, small diameter rotary open-hole drilling which is first and foremost SAFE, fast, clean, quiet, cost effective and environmentally friendly. New Microdrill has been designed for probing for shallow workings in limestone, sandstone and coal as well as locating mine shafts and sinkholes.

Recently Microdrill was in action in Newcastle, Co Durham on the Durham and Northumberland Coalfield. Having previously obtained a coal drilling permit from the Coal Authority to drill with water flush Microdrill was delivered to site on the back of a standard flatbed trailer.

Shallow mine working investigation of a housing estate in Newcastle

Access to the drilling positions in several gardens was tricky but achievable with Microdrill.

In accordance with Coal Authority Guidance on Managing the Risk of Hazardous Gases when Drilling or Piling Near Coal (essentially a Code of practice for safe drilling and piling through coal) water flush was in this instance considered to be the safest flushing medium. This is because there was assessed to be an unknown or undetermined gas risk as is so often the case in exploratory drilling works on the UK coalfields.

The Coal Authority normally stipulates small volume water injection flush for their internally managed exploratory drilling works because it ensures minimal risk to the public from hazardous gases including carbon dioxide, methane and carbon monoxide. In fact it is rare under the Coal Authorities strict safety policy for drilling through coal for them to permit anything else but water.

The Coal Authorities strict policy with regard to water flush is something to be considered by site investigation companies when compiling a Coal Mining Risk Assessment (CMRA) or drawing-up a source-pathway-receptor based risk assessment for drilling permit application.

It should also be borne in mind by drilling contractors and consultants that the CA polices drill sites checking some 10% of drill sites per year to ensure compliance with the permit. A change in drill flush from that originally agreed with the CA would be a breach of terms and conditions and could result in prosecution.

New Microdrill has been demoed to the CA who gave it their nod of approval suggesting that in their opinion it was easily capable of reaching 50m and probably much deeper though up till now it has only been tested to 30m which is typically the limit for shallow mining investigation.

If you require a coal mining investigation, Phase 1 desk study, coal mining risk assessment (CMRA), Phase 2 intrusive site investigation, geotechnical investigation, ground investigation or you need a contaminated land survey or landfill gas survey, trial pitting or borehole drilling please do not hesitate to contact one of our regional offices. Our team are only too happy to assist with your enquiry and will ensure that you get our most competitive quote.