“RMR combines the most significant geologic parameters of influence and represents them with one overall comprehensive index of rock mass quality, which is used for the design and construction of excavations in rock, such as tunnels, mines, slopes and foundations.

Moreover, the system was the first to enable estimation of rock mass properties, such as the modulus of deformation in addition to providing tunnel support guidelines and the stand-up time of underground excavations“.

– From Wikipedia, the free encyclopedia.

“We’re running around here on this tunnel doubting and questioning ourselves all the time as to whether we are properly applying these rockmass classification systems on the assumption that because they appear to have a sound scientific basis they must be accurate and better than relying on more traditional rock descriptions and simple observational techniques. We blame ourselves and not the inadequacy of these systems for not being able to get the numbers right and we blame each other when the numbers for the same rock face don’t match. How typically human and so misguided“.

– Comment by Junior Tunnel Engineering Geologist, 1983

“Like a good Jamie Oliver recipe these classification systems are easy to apply, and they have now become so widely used that sight has been lost by some of their limitations, and, more importantly, of the principals of applied mechanics and structural engineering that should be the basis of tunnel support design. Fortunately, a few papers are now appearing that question the validity of designing using classification systems……

……A final point to note is that Q and RMR values are not factual data in respect to the engineering geology of a rock mass. Firstly, they include a significant degree of interpretation“.

– Extracts from 2003 publication; Limitations of Rockmass Classification Systems for Tunnel Support Design by P. J. N.Pells BSc (Eng), MSc, DSc (Eng), DIC & R. Bertuzzi BE, MSc (Eng)

“Engineers seem to be relying on generalised correlations of rock behaviour with rock mass ratings by Bieniawskis RMR and Bartons Q: yet the assignment of numbers is too schematic, the collection of data from exposures might not be adequately representative, and the assigned parameters are neither independent nor directly connected with rock behaviour“

– Bieniawski and Barton in 2008 in Tunnels and Tunneling International quoting Professor R E Goodmans earlier 2007 criticism of both of their rockmass classifications

“When you can measure what you are speaking about and express it in numbers, you know something about it; but when you cannot express it in numbers, your knowledge is of a meager and unsatisfactory kind.”

– In defence of their systems in 2008 Beniawski and Barton cite Lord Kelvin 1824 – 1907.

“Counting sounds easy until we actually attempt it, and then we quickly discover that often we cannot recognize what we ought to count. Numbers are no substitute for clear definitions, and not everything that can be counted counts“.

– Attributed to Professor William Bruce Cameron in 1958

Interest Rekindled by Recent Events

Recently while working away on another job I was invited to go and have a look at a drill and blast tunnel and to give passing opinion (in other words free advice) on the rock conditions being encountered. The contractor (an old acquaintance) was having difficulty in pulling sufficient metres of rock with each round. The advance rate and progress were much less than expected and undoubtedly the project was heading towards a claim and a dispute over the delays and extra costs he was facing – not an untypical situation in tunneling.

Z.T. Beniawski’s Rock Mass Rating “RMR” System originally developed in 1972 – 1973 had predicted an RMR of 70, ie. Good Rock for the tunnel based on rock cores only as there was no rock outcrop in this case. After inspecting the unweathered poorly jointed, high strength, crystalline rockmass, which was exposed in the tunnel and not covered in dust or tunnel gunge I quickly came to the conclusion after carrying out a few classifications that the RMR was closer to 90, ie. Very Good. In fact the rockmass was verging on massive with few joints, with most of these being widely spaced, sub-vertical, very discontinuous and very tight and rough. There were no sub-horizontal release joints, not even stress or exfoliation related discontinuities. As you would expect in this class of rock, the tunnel was dry, the profile was very good rounded and with minimal overbreak. Absolutely no temporary support, either rock bolts or linings, were required up to the placement of the final lining and even that wasn’t necessary. The contractor’s problem with the advance rate could be explained by the foreseeable difficulty of blasting long rounds in a massive, very high strength crystalline rock with few discontinuities to assist the blast. In other words he needed to reduce the round length and experiment with the blast design.

Once up top I examined several cores which had been laid out in preparation for my visit as well as the original site investigation core photos and borehole logs. Not unexpectedly the cores appeared to have a higher frequency of discontinuities than seen in the rockmass underground even though it had be blasted – again not an untypical observation.

“Tongue in cheek” I suggested that the problems might be because the tunneling conditions were “better than foreseen” in that at tender he had been led to expect a Good rockmass but one with sufficient jointing to allow the higher advance rate he had originally intended, whereas the encountered was 1 full Class better being Very Good with fewer joints, which made blasting more difficult and with a slower advance rate etc.

The difference in support actually installed at the tunnel with that originally predicted (namely none whatsoever as opposed to good rock being spot bolting plus occasional wire mesh) might also provide a measure of the change in conditions, as bolts and wire mesh would be expected to reflect rock with a higher frequency of jointing.

Eureka was the reply!.

Experiences with Rock Mass Rating (RMR) in the 1980s

The occasion reminded me of some 30 years earlier when I was still a relatively inexperienced engineering geologist on the construction of the 13.5 km Hex River Tunnel in the beautiful, mountainous region of the Cape Province, South Africa.

At University a few years earlier I had been taught about rockmass classification – the 2 main systems being the RMR or Geomechanics System developed in South Africa, and Barton’s NGI Q-System developed in Norway. Both had been introduced in the 1970s around the same time though RMR would be published a few years before the Q-System.

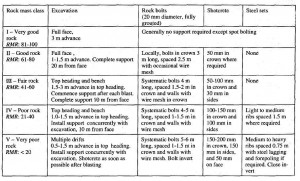

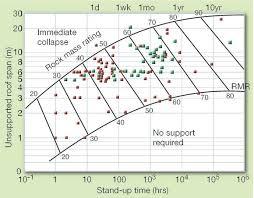

Both numerical systems claimed to comprehensively characterise the various important features of the rockmass, block size and interblock shear strength etc, allocating numbers to each parameter ultimately leading to a final number or rock class, and thereafter a tunnel support output using an additive or multiplicative formula. One system, the RMR, even proffered to be transferable in its application from tunnels, to slopes, to foundations and in later years to rock rippability and mining, though I always wondered how it could be applied upside down, ie. to a tunnel where gravity acted negatively downwards in terms of its affect compared to a foundation where it was a positive factor? RMR could also do even more, and provided a chart giving stand up time, ie. the length of time to collapse in hours, days and years for a given rating and unsupported span.

Such a system, if it worked, would of course be the holy grail of tunnelling that every geologist or engineer was searching for, namely a simple, accurate, reproducible and indisputable way of predicting tunnel support whether for tender purposes or at the face during construction. So not surprisingly by the late 1970s rock classification systems had become very popular and were being applied all over the world, including at the Hex River Railway, where RMR was used.

However, at University we weren’t told about the downsides of rockmass classification systems, their subjectiveness and the scope for disputes they could potentially create – hardly surprising because afterall their use was still relatively new, the numbers were being chosen by humans with different levels of experience, expertise and ability in tunneling, and perhaps with different agendas which might arise, from say being on opposing sides of a dispute.

Neither were we told about the difficulties and differences that might arise when classifying rock cores as opposed to weathered surface rock exposures, or underground when classifying fresh tunnel faces offering 3 dimensions but often blast damaged, or trying to reclassify tunnels several years later when the rock surface and critical features such as shear joints and faults were hidden in dust and tunnel gunge.

Of the many subsequent revisions of the RMR system that would be made in the subsequent years one would in particular, the change in philosophy from straight averaging of the parameters to taking the worst would have very significant implications. The change from straight averaging to using the worst could in itself, depending on which method was being applied, account for a 10 to 20 difference in the RMR value obtained for the same rockmass, and did not include the differences that might arise from all the other subjectiveness and uncertainty and human error in obtaining the parameters in the first place.

Potentially such a major change and the various revisions and later publications of the RMR system could be a basis for disputes in themselves, and it would be imperative to identify and stipulate the date of the RMR publication being used in any tunnel appraisal, particularly for tender purposes, or where a before and after comparison was being carried out. Essentially a claimants tunnel geologist could be rating for the worst while the defendants was averaging and getting a higher value, or the same number as would have been obtained using the contractually correct system included in the tender documents.

And then of course there might be the disputes caused by the difference between the cores and the actual conditions seen underground, and whether the support installed by the claimant was intentionally overly excessive with the purpose of slowing tunnelling and creating the impression of poorer than expected conditions with a corresponding higher level of support, reduced stand-up time and therefore a lower RMR number and Rock Class.

As a lawyer once said to me “if it’s got spots it’s got measles” referring to the inexplicable use of systematic rock bolt pattern in one 300m long section of tunnel in massive, perfectly dry, high strength sandstone with a perfectly arched crown and haunches in a low to moderate stress environment.

Over-support or inappropriate support can be important because the system allows you to work back from the support to a rock class and a number, assuming that the support is all that is needed and is not excessive. After all, Beniawski’s system would have been based on case histories, some hindsight and back analysis, including presumably underground openings where ratings had been carried out on tunnels which had already been supported or left unsupported for possibly many weeks, months or years beforehand. In which case, one would assume that the rock walls would have been thoroughly washed down to fully expose rock and joint surface conditions, and access gantries had been provided to make a proper inspection and classification possible.

Meeting Professor Z.T. Beniawski

At the Hex River Railway Tunnel I remember the day I met Professor Beniawski underground at a freshly blasted face sometime around 1983, some 10 years after the introduction of the Rock Mass Rating system, and some 10 years before the dispute would finally reach the court of arbitration. He had been engaged by the French tunnel contractor (subsequently the claimant) as their tunneling consultant.

As a young, enthusiastic, inquisitive and recently graduated engineering geologist, employed via my company at the time by the South African Transport Services SATS (the defendant), I was keen to discuss and to classify with him the rock conditions together at the tunnel face, and to see how the master (who I was in awe of) applied his own system so that I might learn from him and improve my use of it.

I wanted to ask him about some of the niggly, naggly doubts I continued to have about the system, although I had by this time applied the RMR on many hundreds of occasions and to many different types of rock, including major and minor faults and blocky jointed rock with slickensided bedding. My concerns were namely the changes in his system vis-à-vis averaging of the parameters, as opposed to taking the worst, the subjectiveness of some of the parameters and how they can best be accurately measured, human error and the differences when classification is carried out on rock cores or weathered surface exposures as opposed to underground in freshly blasted, fully exposed, washed down rock face with 3 dimensions visible, but also where blast damage may have an affect.

In addition I wanted to discuss stand-up time – was it really meaningful and how could the RMR be applied to tunneling as well as upside down for a foundation.

Unfortunately, though we spent several hours in the close confined space at the tunnel face, the opportunity didn’t arise where I could exchange notes or classifications with the Professor. Afterwards sitting with him on the train going out we discussed everything but RMR classification. So after the master had left I was none-the-wiser after that encounter on how to best to use his system, and still having all the nagging doubts about its real value as an engineering tool given the question marks I had over such things as averaging vs worst, and my concerns about the stand-up time chart.

With regard to the latter, if stand-up time was unreliable but remained a corner stone of the system (as it seems to be have been given that it is included in every RMR publication and revision) how could the output of the system as a whole be trusted, and moreover its support guidance?

Taking it from another angle, if I came to a section of tunnel where a particular level of support had been installed, say 1 bolt per 1.5m to 2m spacing with mesh, would it follow automatically that the rockmass class could only be Fair, even though it might have been over-supported intentionally or not, and my classification showed it to be Good. In other words, if it has spots – does the patient have measles or has the wrong diagnosis been made by a poor doctor?

In this case, in order to disprove the link between the support installed, its equivalent stand-up time and therefore that the Rock Class wasn’t correct, the support would have to be removed and the stand-up time/behaviour of the opening/patient monitored before a second opinion could be made properly – normally an impossible scenario.

Meeting Dr Ron E. Heuer

Dr Ron E Heuer an American tunnelling expert who I had met on the Hex Tunnel in 1984 and again several times in the arbitration which followed in 1992 was a revelation and a breath of fresh air with respect to rock tunnel support and tunnel construction methods.

Full of expectation at meeting this expert we were somewhat initially disappointed when a bearded Ron Heuer arrived at the tunnel without fanfare, dressed in corduroy pants and open neck shirt, I remember smirking with another young engineering geologist I was working with (as immature grads have been known to do) that surely this cant be the expert we’ve engaged. How will he measure up to the contractors big guns? What were our bosses, who Ron had been highly recommended to, but who hadn’t met him yet (and who were more flamboyant characters) going to think of him?

How wrong we were. This softly spoken, courteous, unassuming, honest, laid back (in the nicest of senses) man would later be described by our legal team as a real tunneling mans tunneling expert (an expert’s expert) with a CV of several hundred tunnels under his belt. That was 1992 and I understand Ron has continued to appraise tunnels for the 20 years that have passed since then, so who knows what his tally must be by now.

Having immediately been asked myself, at my interview for the Hex Tunnel job what classification system I used on the mines to assess tunnel support and answering rather embarrassingly to a perplexed interview panel, “None, we use observational techniques“! In fact we put in very little support at Consolidated Murchison Mine as the rock conditions were generally “good” in the sense of good i.e. having a good profile with mostly few, very tight joints in a medium stress environment even at the maximum depth of 1000m. We also inspected at regular intervals, barred down any loose rock and put in the occasional bolt or split set rock bolt or mesh where there was ongoing concern – ie. sound observational practice.

Therefore after my own interview experience the first question I asked Ron Heuer was what classification system he used. Unabashedly Ron said None ! – he never used rockmass classification systems. Ron’s philosophy was simple, sound and refreshing – “Why try to pigeon hole with numbers what is best described or seen in the core”.

For example if a rockmass is blocky jointed expect it to develop a flat crown and stepped haunch profile which may require 2m long spot or systematic rock bolt support to make safe the roof. In Ron’s book the rock really doesn’t mind whether you called it fair or good, all that matters is that if you don’t put in 6 or 8 rock bolts per round there’s a good chance bits of it are going to fall on you. So allow for systematic support – in or out of cycle – whichever best suits your working methods and come equipped to do the job properly with a rock bolting jumbo and lastly schedule your progress and estimate your costs accordingly with some provision (say 15%) for variation and poorer ground.

I watched Ron inspect the original borehole cores making his brief notes as he quickly moved down the core. After a day or two of looking at some 1000m of core (yes do the calcs there was only some 1300m of core for a 13.5km long, 6m diam. tunnel with a 1 km long double, or loop section of some 12m span with no boreholes whatsoever where incidentally we encountered a major fault running sub parallel to the tunnel axis, proving how appropriate the name Hex was). I asked Ron what he thought. Without hesitation he gave me an honest off-the-cuff assessment of the tunneling conditions he would have predicted on the basis of the tender cores with an estimate of how much “Heuer Good”, Fair, Poor and faulted rock and “Heuer temporary support” he would have expected in terms of percentage length of the tunnel.

In fact he was only too pleased to explain exactly how he had arrived at the figures and to discuss with us the uncertainties and unknowns that remained. No parametric based rockmass classification requiring addition, subtraction or multiplication was involved here. He then said that this was the sort of thing he does routinely in the USA for contractors who are tendering for tunnel projects as practical tunnel contractors just wouldn’t understand what a number meant and they wouldn’t be interested either.

Over the 2 years of the arbitration hearings we came to fully appreciate Dr Heuer’s extensive and sound academic and technical knowledge as well as his vast practical tunneling expertise and his honesty. If Ron Heuer said this is the way a tunnel should be built you wouldn’t doubt for a moment that it wasn’t the right way.

Subsequently, it turned out that when originally the winning tunnel tender was formulated the highly experienced tunneling engineer who made it had paid little or no attention to the RMR classification included in the tender documents and which at that time was still relatively novel having only been introduced some 5 years before the site investigation report was completed. Apparently to his credit however he had foreseen the use a rock bolting jumbo, though this flexibility to deal with possible variation in the rock condition that might be encountered and particularly poorer conditions would subsequently be withdrawn to the grave detriment of the completion date and cost of the project which overran by many years and was way, way over budget resulting in one of the worlds largest claims for “Unforseen adverse tunneling conditions”.

Another tenderer’s geologist had raised a red flag about concerns about flexural slip and the disturbance this may have caused to the rockmass along the tunnel route in this highly folded mountainous region comprising flexed, blocky jointed and sometimes faulted interbedded sandstone and shale strata, though no mention was made of the RMR predictions that had been provided in the tender document. However, they didn’t get the job because it went to the lowest bidder who would go on to become the claimant who in the end had not come to site with a bolting jumbo capable of installing support without disrupting the tunnel cycle.

Another Rockmass Classification System?

Soon after arriving at the tunnel from the mines I recollect the young engineering geologist colleague (also from Portsmouth) who I was replacing at the Hex Tunnel saying on several occasions that he was going to develop a new rockmass classification to compete with RMR and Q, both because it would be a very interesting and meritable scientific exercise but also a way of making him rich and famous. He was really serious about this.

He said – “can you imagine a new system with even more input parameters and with the same subjectiveness and uncertainties as the existing systems as well of course the subjectiveness and potential unreliability that accompanies its unavoidable need for human input and manipulation.

Throw in several changes with several subsequent revisions and publications, one or two major changes in methodology ie averaging vs worst and you can you imagine the demand there would be for my services both to explain how the system works and to advise one or other parties in a tunnel dispute where my system had been used as the basis of the tender or to act as expert witness or arbiter though of course the later would all be unintentional though not unwelcome by-products“.

In reply I would say you’re daft – though I don’t think so any more.

My colleague would also say – “we’re running around here on this tunnel doubting and questioning ourselves all the time as to whether we are properly applying these rockmass classification systems on the assumption that because they appear to have a sound scientific basis they must be accurate and better than relying on more traditional rock descriptions and simple observational techniques. We blame ourselves and not the inadequacy of these systems for not being able to get the numbers right and we blame each other when the numbers for the same rock face don’t match. How typically human and misguided” he would say.

With respect to RMR I still have major concerns about the credibility of the stand-up time chart included in each of the umpteen revisions and publications of the system. Having classified many unsupported sections of civil and mine tunnel (some 30 years old and much older) I have found little or no correlation between the numbers I get and the time output.

If this is the case and stand-up time remains an intrinsic part of the RMR system as it seems to be and there are other longstanding arguments about the systems overall subjectiveness, as well as whether it can at the same time meaningfully represent a wide range of very different engineering uses (namely tunnels, foundations and slopes and subsequently even rock rippability) one has to be sensibly realistic when assessing its true value as a reliable, reproducible and accurate engineering geological tool.

Using RMR Again?

Therefore the obvious question that follows – would I use RMR again as such a tool. My answer would be No. Now that I’m older, more experienced and more confident and prepared to speak out about the inconsistencies I found with the RMR system it wouldn’t be my first choice.

Finally I leave you with one of the early views in the 1970s that the introduction of the RMR would reduce for the scope for disagreement and disputes between the parties involved in tunneling because essentially we would all be talking the same language or numbers.

I have the opposite opinion in that I feel that it gives the claimant an easier ride to drive a claim solely based on number differences. My experience is that the defendant is always on the back foot having to justify that their way of getting the numbers is correct, with the suspicion that if our numbers were high they were being manipulated. I found that this put pressure on the defendant’s engineering geologists to move closer to the claimant’s numbers in order to avoid the accusation of being overly optimistic if not downright biased. On the other hand the accusation against the claimant that their classifications were too low might be met with the argument from their engineering geologist that they were not using an average, but a weighted average or the critical discontinuity in their assessment or the worst. All the better then if you could also claim that the inventor of such a system broadly agreed with how you classified the rock and the numbers you got.

With regard to proving that the claimant had intentionally over-supported, this is not an easy thing to do given that in general the tunneling contractor, who has the responsibility for the safety of his workers and for making snap decision at the rock face on support, will invariably and understandably be given the benefit of the doubt on this issue providing they are careful and there is correlation between the numbers, tunnel profile, control or overbreak, the support density and tunnel progress.

Overbreak would however be more difficult to manipulate and the game might be up, if for example there was shown to be little or no correlation in overbreak between different rock classes or where the overbreak in a long section of tunnel where the predicted Good rock conditions had actually been encountered was found to be excessive.

With regard to using Lord Kelvin as a justification for turning rockmasses into numbers while at the same time mocking simpler, traditional, non-numerical description this would I’m sure in the opinion of most of us be as brazen and nonsensical as claiming that without numbers we cannot identify, speak or describe the things that make a portrait truly beautiful or a marble sculpture exquisite. Indeed if you tried the numbers game at the Tate Modern to evaluate a Damien Hirst creation you would be laughed out of the gallery. Not so in the apparently less bohemian world of tunnel engineering geology though the subject is just as complex and as difficult to capture as the artist’s model.

So do I think that rockmass classification system have been a waste of time. No – like any good work tool they have their place in the engineering geology workshop providing the servant knows its place and the master knows the servants limitations – and most importantly the servant never becomes the master. This is unfortunately what was allowed to happen to us (then young engineering geologists) on the Hex Tunnel in 1983.

There is no doubt that over the past 40 years rockmass classifications have provided a tremendous amount of useful discussion (often heated) and important ongoing scientific investigation about what are the important features in a rockmass that make it stable or unstable in the tunnel setting, and what support is appropriate. There is nothing wrong with this, provided the limitations of rockmass classification are fully recognized and shared between the engineering geological and tunneling communities, and those that prefer to use traditional observational and descriptive techniques are not made to feel that their knowledge is meager, unsatisfactory and that their approach is less scientific or outmoded.

As I have said, I and increasingly others in recent years (and even the criticism made early on in 1970s and the 1980s) believe that good engineering geological description of a rockmass is more important than pigeon holing it with numbers. While rock description should be of importance together with the rocks other engineering and mechanical properties, there is a place for rockmass classification systems but only as a much lower order check. They should never be included as a contractual tool, and should never be shown on borehole logs and tunnel long sections unless very good reasons can be given to do so.

The author has found that Pells provides a very useful discussion on what is important in obtaining and preparing geotechnical information for underground works and how to analyse and present it. This is broadly in keeping with the methodology applied by Dr Ron Heuer in 1984 at the Hex River Tunnel. Dr Heuer’s philosophy was that a contractor can expect x amount of “good” rock and y amount of fair and z amount of poor etc (whatever you want to call it provided you properly describe what it is and what it means – in terms of tunnel shape, overbreak, stability, support density, water inflow, advance rates and construction equipment) with some allowance for variation. Often we can’t be exactly sure where z is going to occur in the tunnel, but it is to be expected and therefore a good tunneling contractor should tool-up properly and cost accordingly with some contingency for worse conditions. Rockmass classifications and their numbers are much less meaningful to a tunneling contractor.

Further Reading:

Geotechnical Models for Underground Works – Pells Consulting

PART 2. NOTES ON THE PREPARATION OF GEOTECHNICAL MODELS … computation methods for the design of underground works is very limited. There is …

About The Author

Ross Nicolson BSc (Hons) MSc Eng CEng MIMM is Principal Geotechnical Engineer at GeoInvestigate, with over 30 years experience in site investigation, engineering geology and geotechnical and geo-environmental engineering both in the UK and in Africa. Ross’ main areas of interest include borehole investigations, desk studies, site investigations, dams, tunnels, roads, slopes, pipelines, old mineworkings, foundation, building subsidence and contaminated land investigations.

From their offices across England, Geoinvestigate provides a reliable, cost effective, nationwide site investigation service. We provide expertise in the fields of site investigation, ground investigation, soil investigation, foundation investigation, engineering geology, geotechnical engineering, Phase 1 desk study and preliminary risk assessment, Phase 2 site investigation reports, geotechnical consultancy, environmental consultancy, geo-environmental consultancy, landfill gas and mine gas surveys and monitoring, contaminated land assessment and contaminated land remediation, building subsidence, slope stability, mineworkings, contaminated land validation surveys as well as data acquisition and soil surveys using trial pits, boreholes and soil and rock drilling.